The VSHOOTER+®–3–WL, the ideal tool for predictive maintenance of rotating machinery.

The VSHOOTER+®–3–WL is a rotating machine vibration analyzer that works with a wireless triaxial sensor and a rugged smartphone with on–board data processing software.

Standard version VSHOOTER®-3-WL

Standard version with thermal camera (80×60 px, 9Hz) VSHOOTER®-3-WL-IR

Standard version with thermal camera HD (256×192 px, 25Hz) VSHOOTER®–3-WL-IR HD

Standard Version ATEX certified (Smartphone Ex ib Ⅱ CT4Gb, Capteur Ex ia Ⅱ CT4Ga) VSHOOTER®-3-WL EX

![]()

In the main menu of the device you will have two choices to perform a vibration analysis.

The first is multimeter mode ![]() and the second is MCP Mode (Machine Condition Picture)

and the second is MCP Mode (Machine Condition Picture) ![]() .

.

Then you will have the global settings of the application and the memory stock of the analyses and images you have saved.

In addition, the wireless triaxial sensor will be a key asset to save time on your measurements. Indeed, it will allow you to measure all three measurement axes (Horizontal, vertical, axial) at the same time.

Finally, when it comes to the placement of the triaxial sensor, simply put it in the direction of alignment of your machine.

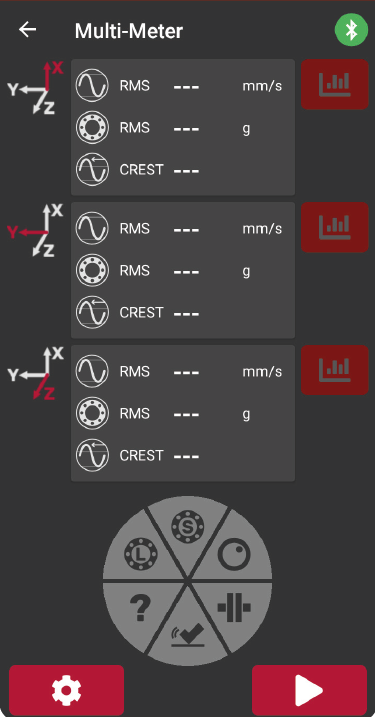

The Multimeter Mode of the device takes place in three stages.

– The launch of the multimeter mode.

-The parameters to be filled in of the machine before the vibration analysis (ISO group of the machine and the bearing per minute or RPM).

– After doing these two steps and placing the wireless triaxial sensor on the machine, you can start the vibration analysis.

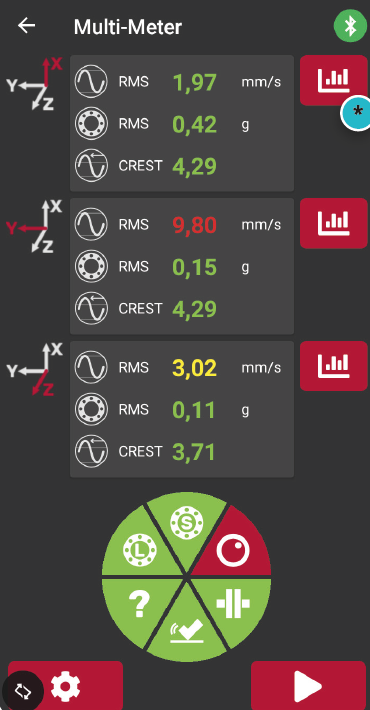

– Finally, the purpose of this analysis will be to identify the defects of your rotating machine quickly and efficiently.

The defects that can be perceived are:

Imbalance, misalignment, foundation defects, bearing shocks and finally bearing lubrication.