Meet the first compressed air leak detector with steam trap control software!

Meet the first compressed air leak detector with steam trap control software!This LEAKSHOOTER®+ version becomes the maintenance technician‘s triple ally thanks to its steam trap control function.

Indeed, the LEAKSHOOTER V3+PRO has three skills:

Detection of leaks of gaseous fluid under pressure,

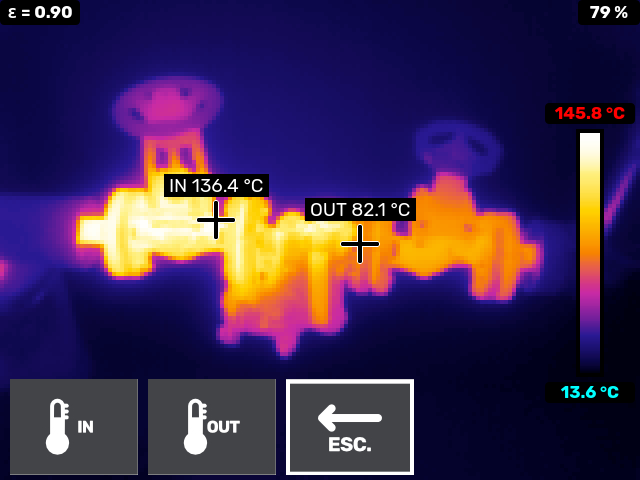

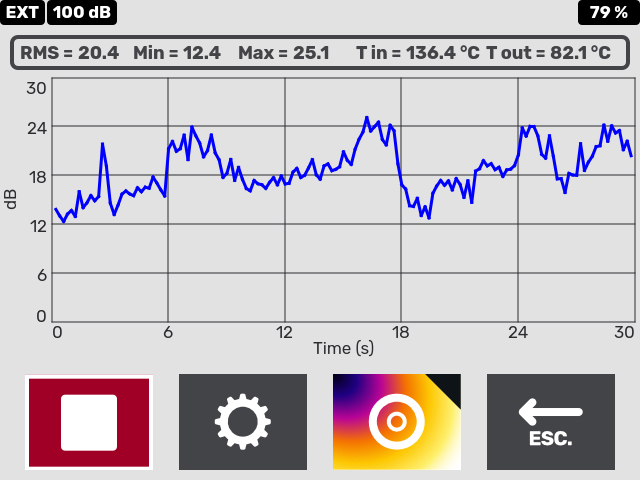

Steam trap control with its STRAPSHOOTER program,

And finally, the detection of hot spots via its integrated thermal camera.

![]()

From now on, do not wait until the situation becomes dangerous to inspect your steam traps. For instance, water hammer indicates a condensate drainage issue in your steam system, which can damage your equipment and even pose safety risks.

Moreover, if a steam trap is stuck open, live steam will be discharged into the condensate recovery circuit, leading to significant energy and financial losses.

That’s why we recommend regularly checking your steam trap installations with the LEAKSHOOTER®V3+PRO. Thanks to its dual embedded technology—infrared camera and ultrasonic sensor for acoustic analysis—and its fully integrated automatic diagnostic firmware, you can detect faulty traps in just seconds.

Remember, approximately 40% of your steam traps are likely in poor condition, and about 20% of steam is lost through leaking traps.

With the LEAKSHOOTER®V3+PRO, optimize your energy efficiency!

The LEAKSHOOTER® V3+PRO and its range come with several accessories that provide valuable assistance depending on the application and working environment: