Advanced technology for the detection of industrial leaks and anomalies

Ultrasound is an acoustic vibration whose frequency is too high to be perceived by the human ear. These sound waves, with frequencies exceeding 20 000 Hz, are used to monitor a wide range of industrial phenomena that are invisible to the naked eye.

Why use ultrasonic inspection?

Ultrasonic inspection is a powerful and essential tool for identifying various problems in industrial systems. Unlike audible sounds, ultrasound can detect anomalies that affect equipment performance without interrupting operation.

Applications of ultrasonic inspection

Ultrasound can detect a variety of undesirable phenomena, such as:

- Compressed air and pressurized gas leaks

- Vacuum leaks in installations

- Turbulence in fluid circuits or steam traps

- Bearing defects and lubrication problems

- Electric shocks and crown effects in electrical systems

- And many other anomalies invisible to the naked eye.

These detections help prevent costly failures and ensure optimal performance of your equipment.

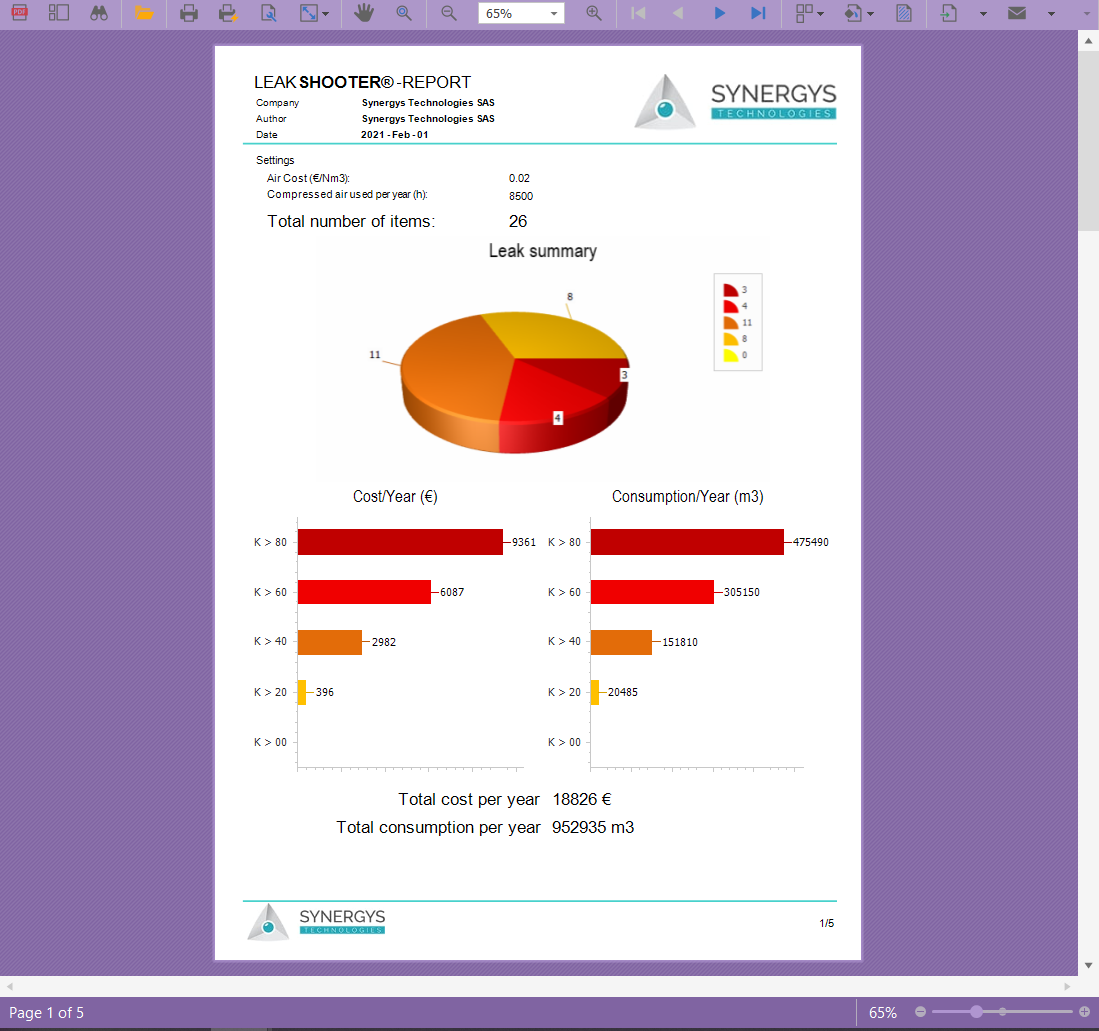

Function K: Evaluation of the cost of compressed air leaks

Compressed air is a crucial element in many industries, but it is also one of the most expensive. Compressed air leaks can cause significant energy losses, increasing operational costs. Rapid and effective leak detection is therefore essential to maximize energy efficiency and reduce costs.

Air leak detection: The revolutionary LEAKSHOOTER tool®

SYNERGYS TECHNOLOGIES has developed an innovative solution to solve this problem: the LEAKSHOOTER®. This device allows for real-time ultrasonic leak detection, while simultaneously allowing simultaneous viewing and listening of ultrasound. This allows you to precisely locate air leaks in your facility without disrupting its operation.

Why invest in the LEAKSHOOTER®?

- Improved energy efficiency: With fast and accurate detection, LEAKSHOOTER® helps you save energy by identifying costly compressed air leaks.

- Cost savings: By identifying leaks, you avoid having to install additional compressors to compensate for air loss, resulting in significant savings.

- Increased performance: Using the LEAKSHOOTER® keeps your systems in perfect working order, avoiding breakdowns and optimizing equipment life.

Ultrasonic inspection and LEAKSHOOTER® are essential tools for any company that wants to optimize its costs and improve the performance of its industrial equipment. With this advanced technology, you can quickly and accurately identify leaks and faults in your facilities while reducing energy and operational costs. Opt for proactive and intelligent maintenance with SYNERGYS TECHNOLOGIES.