The VSHOOTER®+WL is the ideal tool for predictive maintenance of rotating machinery.

Indeed, the VSHOOTER®+WL automatic analyzer is capable of quickly identifying vibrational faults in rotating machines such as electric motors, pumps, fans, bearing housings, or machine tool spindles.

The faults that can be detected include:

Imbalance, misalignment, foundation defects, bearing impacts, and bearing lubrication issues.

To take a vibration measurement of your machine, simply press the icon ![]() .

.

The triaxial sensor is placed as close as possible to the bearings of your machine with a single positioning.

This positioning will depend on the type and style of your rotating machine.

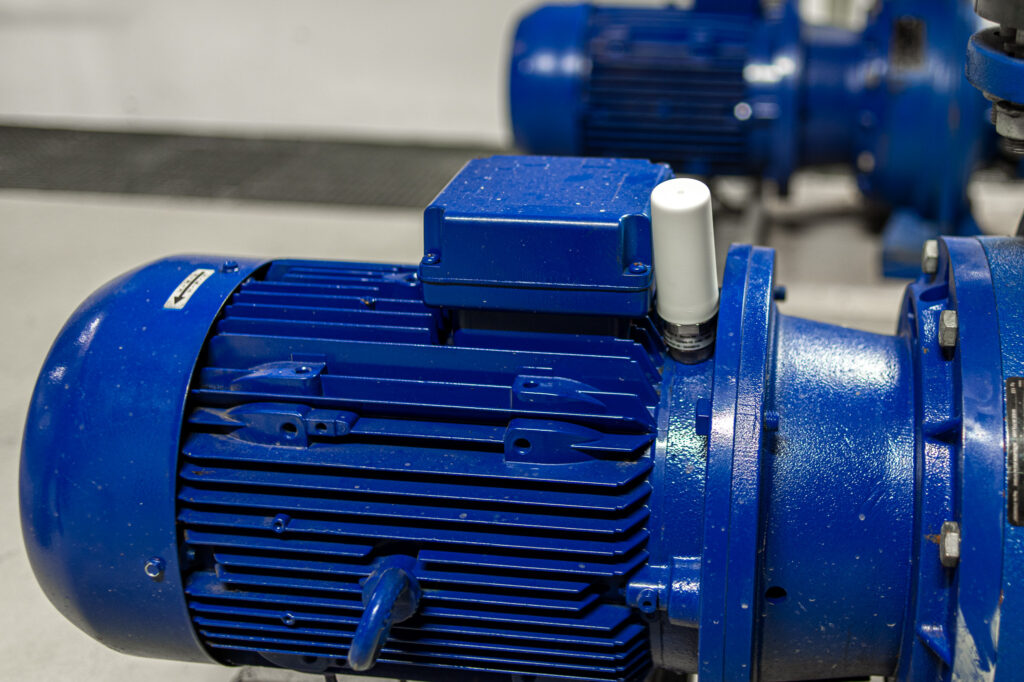

In the photo, the triaxial sensor is placed in the machine axis coordinate system and as close as possible to the bearing.

The VSHOOTER®+WL also features an infrared thermal camera (160×120 pixels). This will allow you to monitor hot spots on your machines, particularly the heating of your bearings.